Floating wind: Technological advancement waiting on economic feasibility

Renewable offshore energy technologies are an important focus point for the ambitious energy and climate targets set by the EU for 2030 and 2050. Offshore wind is leading the charge, but as we look further down the sea, the traditional bottom-fixed design become less feasible. But where there are challenges, there is innovation: Floating turbines, coined as floating wind, can be deployed deeper into the sea, where they can capitalize on the stronger and more consistent wind. Although the technical feasibility of deep-water floating wind turbines isn’t questioned, the economic achievability is.

Why floating is the next step for Europe

The EU has helped develop wind power thanks to ambitious policies and investments. The first offshore wind farm was installed in Denmark in 1991. Europe maintained her leading position and is now a global leader in the manufacturing of key wind turbine components, as well as in the foundations and cables industry. Almost half of the active companies in the wind sector (on- and offshore) are headquartered in the EU. It is of no surprise that further development of this technology is Europe based. The newest challenge is to deploy offshore wind turbines in water depths too deep for fixed-foundation turbines. This is especially important in countries with limited shallow waters, such as France, Japan and the United States’ West Coast.

The left side turbine is a monopile turbine directly connected to the seabed. The floating turbine in the middle makes use of a tension-leg anchoring system, while the right floating turbine is anchored by a catenary loose mooring system.

(Source: Econopolis Strategy)

Although floating wind removes the need to directly connect the turbine to the sea floor, the overall composition remains similar. The turbine is placed on a floating structure that is held in place by anchoring systems attached to the seabed. The two most common types of these anchoring systems are tension-leg and catenary loose mooring systems. The first one has vertical tethers under tension for restoring moments in pitch and roll while the latter provides station-keeping with little stiffness at low tensions. These anchoring systems make it possible to build turbines further down sea in areas with more depth, preventing the immense cost of having to make the turbines large enough to make direct contact with the seabed. Of course, thorough analysis is required to ensure the floating structure provides enough buoyancy to support the weight of the turbine and limit the pitch, roll and heave movements. The design standards for floating wind require a loads analysis based on site-specific conditions such as wind, wave and currents.

Floating wind has more to offer than solely solving the water depth issue. It reduces the visual pollution (“not in my backyard”), provides better accommodation for fishing and shipping lanes, while simultaneously make use of stronger and more consistent winds to generate clean energy. The range of possible areas for wind energy also increases substantially, alleviating competition of sea-usage between different sectors.

How feasible are floating wind turbines today?

The first large-capacity floating wind turbine was “Hywind” (2.3 MW). It was constructed by Siemens Wind Power and deployed in the North Sea near Norway in late 2009. The 120 m tall tower was mounted on a floating tower with a 100 m deep draft. By 2016 the turbine had produced 50 GWh with a capacity factor of 41%, which means it produced 41% of the energy it would have produced, had it been constantly turning in optimal wind conditions for the same period. All this while surviving 40 m/s wind speed and 19-meter waves, which is considered hurricane weather, with seemingly no wear. Clearly, the technical innovation for a floating turbine is mature enough.

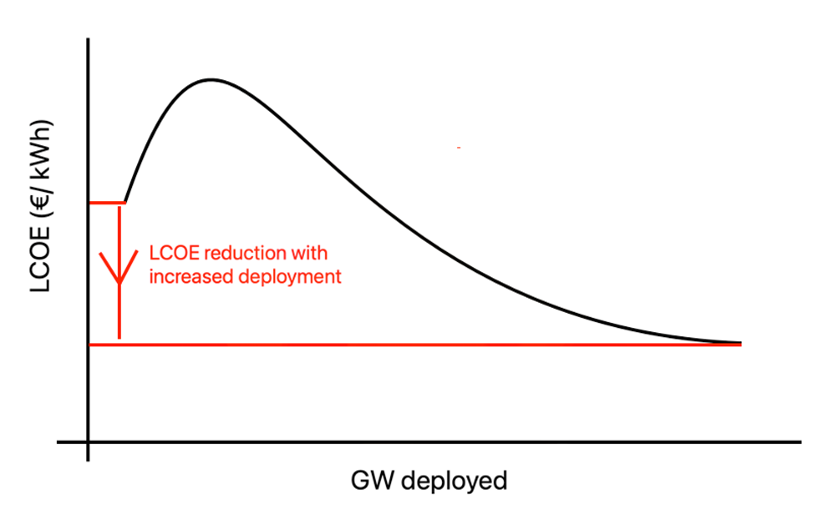

The biggest hurdle for this technology can be found in the economics. In 2021, a French auction closed below an LCOE (levelized cost of electricity) of € 120 for a 250 MW project, which is about twice the LCOE of a traditional installation. This high cost, small project size and lack of experience keep project developers and financial institutions from committing to this technology. But just like the evolution in cost reduction for non-floating offshore wind parks in the last decades (and for all green technologies for that matter), it is believed floating wind will follow a similar pattern. The LCOE will be reduced naturally over the time, but the bigger LCOE reducer comes from deployment, according to statistics from normal wind turbines.

Reduction of LCOE for high deployed capacity, compared to LCOE for low capacities. (source: Econopolis Strategy)

The LCOE reduced heavily for higher deployment rates. It is therefore wise to focus on optimising these rates by optimising the supply chain, learning rate, efficiency in scaling, serial production and so on. Floating wind still has some hurdles to overcome, but a major contributor to the floating wind evolution, Equinor, is optimistic. They also believe in economic scaling to reduce the floating wind costs. Between their Hywind Demo and Hywind Scotland, they saw a reduction in construction cost of 70% and expect a further 40% drop between Hywind Scotland and their newest project Hywind Tampen. They also state that investment in technological improvements will further reduce costs.

Floating wind is the key to unlocking immense green energy production. While technical feasibility is already a non-issue, developments need to be made to make floating wind economically more viable. Following the trend of other wind technologies, companies in the wind sector are optimistic that floating wind can become the next large scale green energy producer!